With the increasing use of robotics and automation on production lines, various manufacturing sectors are able to reduce costs, provide more consistent quality products, and increase profit margins. But how much automation does your packaging line really need?

Simply eliminating workers and supervision from the production line does not always improve efficiency. Manufacturers should understand the requirements of their production lines to choose the right level of automation. Can semi-automatic or fully automatic packaging equipment meet their needs?

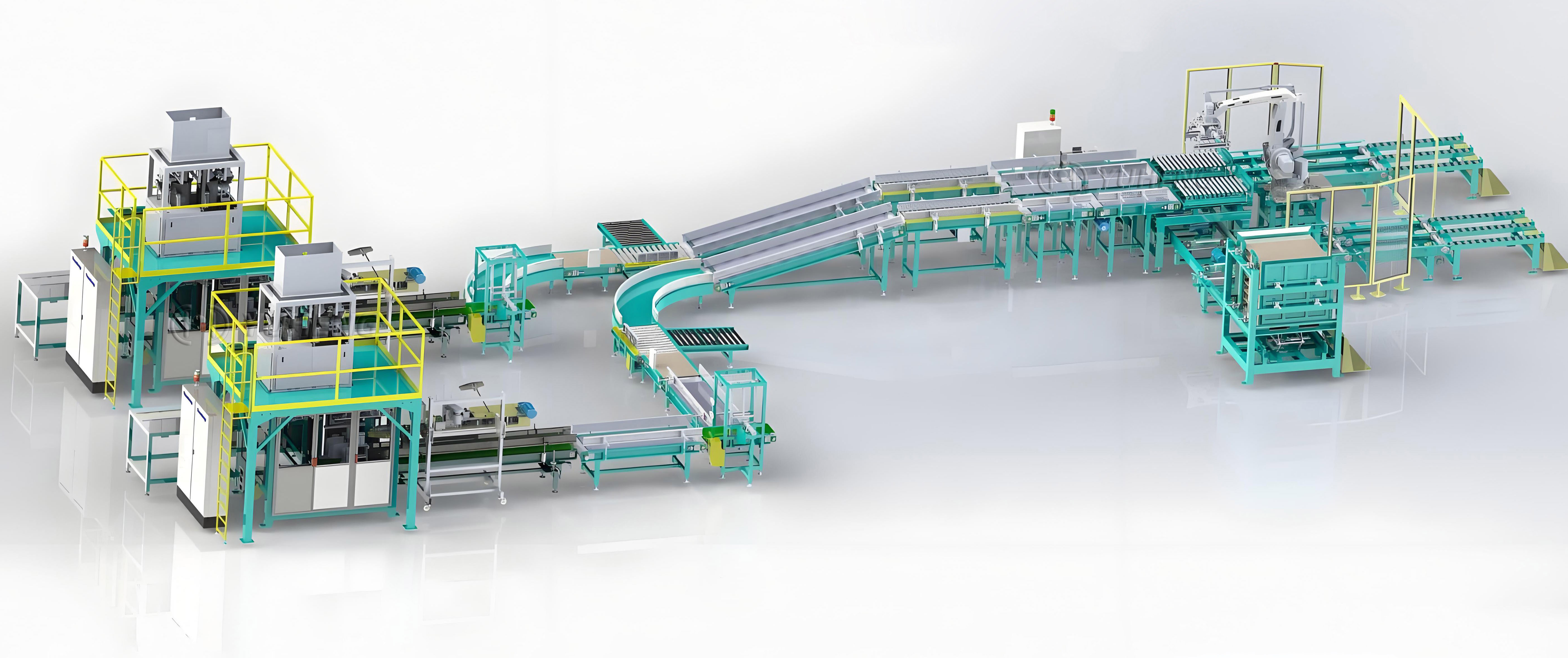

When deciding to use semi-automatic or fully automatic packaging machines on your production line, weigh the relationship between packaging operations and employee interaction and skills, quality, safety, productivity, and profitability. By implementing a fully automated system, manufacturers can eliminate a large amount of labor from the production line and improve production efficiency.

In addition, fully automated production lines help ensure the safety of employees on the production floor. As the design of automated equipment improves, employee interfaces are safer, employees can increasingly interact with equipment without compromising safety, and skilled workers can interact with automated equipment remotely. Fully automated equipment can help improve the safety of employees on the production line without compromising product quality.