In the era of sustainable agriculture, powdered organic fertilizer has emerged as a game-changer due to its high nutrient retention and environmental benefits. If you're looking to optimize your organic fertilizer production, investing in state-of-the-art powdered organic fertilizer equipment is the key to success.

Our equipment employs a three-stage fermentation process—premixing, turning, and refining—to break down organic materials into nutrient-rich powder. This process ensures that macromolecular organic compounds are decomposed into absorbable small molecules, enhancing fertilizer efficacy. The fermentation system is designed with precision temperature control, reaching 60-70°C to eliminate pathogens and weed seeds while preserving essential nutrients.

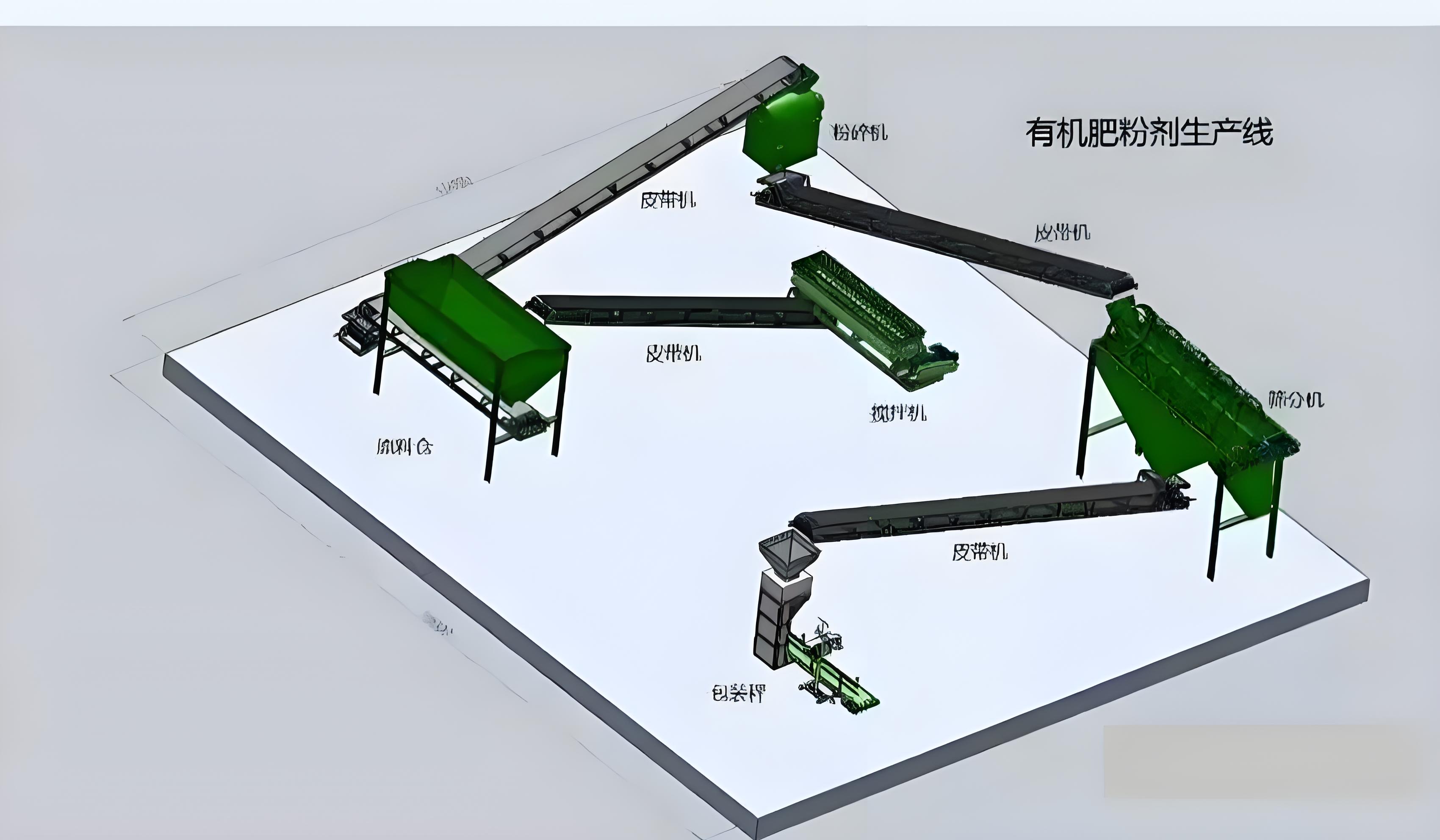

Whether you're a small-scale farm or a large industrial producer, our equipment can be tailored to your requirements. Basic setups include a turning machine, loader feeder, vertical crusher, drum sieve, and packaging machine. For high-moisture raw materials like pig manure or distiller's grains, add a solid-liquid separator to improve efficiency.

The equipment produces powdered organic fertilizer with ≥40% organic matter content and ≥5% total nutrients, meeting national standards. By eliminating unnecessary drying and crushing steps, it reduces operational costs. For example, the new-type organic fertilizer granulator processes raw materials with 20-40% moisture directly, saving energy and time.

Upgrade your organic fertilizer production with our advanced powdered organic fertilizer equipment. Contact us for a free consultation and discover how we can help you achieve sustainable, profitable, and eco-friendly operations.

Zhengzhou Yuheng Technology Co., Ltd

📞 0086 198 0387 1008 | 🌐 https:yhxhmachine.com | 📧 info@zzyhpacking.com